Anzeige

Meldung des Tages: Nasdaq-Biotech-Highflyer – Ergibt sich hier jetzt eine seltene Kaufchance?

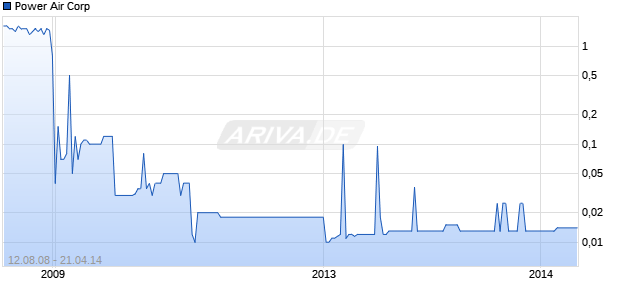

Power Air Corp

Aktie

WKN: A0YBWB ISIN: US7391912034

Keine aktuellen Kursdaten verfügbar

Depot/Watchlist

Dieses Wertpapier ist nicht mehr handelbar.

Marktkapitalisierung *

-

Streubesitz

-

KGV

-

Index-Zuordnung

-

- Push

- Intraday

- 1W

- 3M

- 6M

- 1J

- 5J

- Gesamt

Werbung

Mehr Nachrichten kostenlos abonnieren

E-Mail-Adresse

Bitte überprüfe deine die E-Mail-Adresse.

Benachrichtigungen von ARIVA.DE

(Mit der Bestellung akzeptierst du die Datenschutzhinweise)

(Mit der Bestellung akzeptierst du die Datenschutzhinweise)

Vielen Dank, dass du dich für unseren Newsletter angemeldet hast. Du erhältst in Kürze eine E-Mail mit einem Aktivierungslink.

Leider können wir deine Anfrage auf diesem Weg nicht entgegennehmen.

Bitte schreibe uns an: portal.support@ariva.de

Bitte schreibe uns an: portal.support@ariva.de

Termine

Keine Termine bekannt.

Prognose & Kursziel

Keine aktuellen Prognosen oder Kursziele bekannt.

Stammdaten

| Aktientyp | Stammaktie |

Community-Beiträge zu Power Air Corp

Pate100

Successfully Demonstrates World's First Zinc Air

2/12/2007 1:24:47 PM ET News Release Index

Power Air Successfully Demonstrates World's First Zinc Air Fuel Cell Powered Indoor Generator and Design Prototype at Fuel Cell Expo 2007

LIVERMORE, Calif., Feb. 12 /PRNewswire-FirstCall/ -- Power Air Corporation (OTC Bulletin Board: PWAC - News) completed a three day demonstration of its Zinc Air Fuel Cell ("ZAFC") powered indoor generator prototype, as well as introduced the design prototype produced by its Asian Joint Venture partner, H-Plus Eco Ltd., at the Fuel Cell Expo 2007 in Tokyo, Japan.

"To date, Power Air has been demonstrating its Zinc Air Fuel Cell powered demonstration generator only to potential business partners covered under Non- Disclosure Agreements," states Mr. Donald Ceci, VP Sales and Marketing at Power Air. "Fuel Cell Expo 2007 was the ideal setting to unveil our exclusive technology to a wider audience, and to attract further Asian distribution and development partners to work with our Asian Joint Venture."

The fuel-cell based generator demonstration unit is powered by Power Air's ZAFC running on zinc fuel, which is non-flammable and non-explosive. Because there are no harmful emissions, Power Air's generator has the unique and exclusive advantage of being able to run indoors without the fear of carbon monoxide poisoning to the end user. The company emphasized these advantages by running the demonstration in a centre stage Seminar at the Fuel Cell Expo.

Near term applications for the indoor capable generator range from backup power for apartments, homes and businesses during power outages, to emergency power use for police, fire, homeland security, and disaster recovery.

"ZAFC based generators have the potential to revolutionize the back-up power industry," states Mr. Remy Kozak, President and CEO of Power Air. "Not only do we reduce emissions and offer a sustainable alternative to the traditional generator solutions, our technology creates a completely new market for extended run indoor backup power and positions us as the industry leader."

In addition to demonstrating its generator prototype at the Fuel Cell Expo 2007, Power Air plans to participate in the Hannover Messe -- the largest Energy and Industrial Trade Fair in the World, in Germany in mid-April, 2007, where over 100 companies and research institutions from 25 countries will reveal their latest products and developments. Power Air will demonstrate its indoor generator at Hannover Messe, as well at Alternative Energy 2007, a premier alternative energy and clean energy technology event, in Chicago in late April, 2007, and at the Hydrogen and Fuel Cells 2007: International Conference and Trade Show in Vancouver, Canada in April, 2007. These two events offer Power Air the opportunity to expose its technology and discuss collaboration on commercial products with both North American and International partners.

About H-Plus Eco Ltd.

H-Plus Eco Ltd. was founded in Nov. 2000 and is a leading company in environmental consulting, engineering and construction for contaminated soil and wastewater in Korea. H-Plus has an excellent business network with refineries, engineering companies and motor companies in Korea such as GS Caltex, GSE&C and Hyundai/Kia Motors. Recently H-Plus Eco has started business with Reliance and HPCL in India and FPC in Taiwan.

About Alternative Energy 2007

Alternative Energy 2007 is a premier alternative energy and clean energy technology event, in Chicago in April, 2007. Alternative Energy 2007 will bring together an audience of more than 2,000 senior executives from around the world for five days of highly focused speeches, company presentations and networking, www.ae2007.com

About Hydrogen and Fuel Cells 2007

Hydrogen & Fuel Cells 2007: International Conference and Trade Show from April 29 - May 2, 2007 in Vancouver, Canada will highlight global activities and state-of-the-art hydrogen and fuel cell products, technologies and demonstrations. Attendees will be presented the latest scientific breakthroughs, commercial opportunities and policy developments from the world's prominent hydrogen and fuel cell experts. www.h2fcc.ca

About Fuel Cell Expo 2007

Fuel Cell Expo 2007 is endorsed by the US Fuel Cell Council, World Fuel Cell Council, Hydrogen and Fuel Cells Canada, Fuel Cell Europe, and several other fuel cell associations. Fuel Cell Expo 2006 presented 404 leading companies from over 14 regions and 23,039 visitors from countries worldwide. www.fcexpo.jp

About Hannover Messe

Hannover Messe is the largest Energy and Industrial Trade Fair in the World. Hannover Messe 2006 was attended by 5,175 companies from 66 countries worldwide. www.hannovermesse.com

About Power Air Corporation

Power Air Corporation, with head office in Livermore, California, is engaged in the business of developing, manufacturing and marketing fuel cell based commercial products. Power Air has the exclusive worldwide license to zinc-air fuel cell technology that has been developed at the Department of Energy's Lawrence Livermore National Laboratory, in Livermore, California, for all fields of use (portable, stationary, light mobility and transportation applications) and commercialization.

For further information please call +1-925-960-8777 or visit our website at http://www.poweraircorp.com.

Investor Relations call +1-866-734-7026 or e-mail to investors@poweraircorp.com.

Pate100

netter Anstieg

aber Vorsicht was schnell steigt fällt auch wieder schnell :-)

Pate100

the next step

Power Air Signs Memorandum of Understanding for Generator Fuel Supply and Recycling

Dated: February 6, 2007 Trading Symbol: “PWAC” (OTCBB)

Power Air Corporation today makes the following announcement:

Power Air Signs Memorandum of Understanding for Generator Fuel Supply and Recycling

LIVERMORE, Calif. /PRNewswire-FirstCall/ -- Power Air Corporation (NASD OTCBB: PWAC) today announced the signing of a Memorandum of Understanding with Autobotics, Inc. (“Autobotics”) of Brooklyn Park, Minnesota.

Under the terms of the Agreement, Autobotics will collaborate with Power Air to set up a North American based company to supply, distribute, and recycle the zinc and electrolyte required to fuel the world’s first indoor generator.

"Through this agreement the distribution model will be defined to supply competitively priced fuel to power our first commercial products in North America”, states Mr. Remy Kozak, President and CEO of Power Air. "Recycling of the zinc-oxide (“ZnO”) produced by our product not only completes the “green” cycle but also significantly reduces costs of operation.”

Power Air intends to commercialize its exclusive Zinc Air Fuel Cell (ZAFC) technology worldwide and has already signed several partnering agreements related to distribution of zero-emission, back-up power generators suitable for indoor and outdoor use. End-users will fuel these indoor capable generators with non-flammable, non-explosive, non-polluting zinc fuel and electrolyte. Under the terms of the MOU, Power Air and Autobotics will generate a business plan for the creation of a separate fuel supply and recycling company, and finalize the structure and ownership of the new entity.

“Partnering with Power Air represents a tremendous business opportunity for Autobotics,” states Mr. Walter Walczak, President and CEO of Autobotics, Inc. “The cost differential between recycling Zinc and producing “fresh” Zinc from mines combined with the huge potential back-up power markets that Power Air is addressing make this a very lucrative segment to get into now. ”

“The recycling, or processing, of zinc oxide, into zinc metal, is a potentially sustainable, high volume, opportunity for the global zinc industry,” states Johan Van Wesemael, Manager, Technology & Market Development, International Zinc Association. “The ability to re-cycle and re-use the same fuel provides a competitively priced, sustainable energy source.”

The Zinc Energy Storage Consortium (“ZESTec”) has previously stated that “the availability of zinc as a fuel source, and the ability to recycle the ZnO, pose no limitations to the adoption of zinc fuel cell technology. Zinc is a known global commodity. Zinc fuel cells convert commercially available zinc products into zinc oxide, a known secondary feed material for existing zinc smelters. With a global transportation infrastructure and processing technology available around the world, facilities are easily accessible for recycling.”

“North America is looking for alternate fuel solutions that are green, sustainable, non-polluting, safe, and will reduce our independence on foreign fossil fuels,” adds Mr. Walczak. “We intend to provide this solution.”

About Autobotics, Inc.

Autobotics, Inc. is a North American based company specializing in providing manufacturing solutions, including production, packaging, and automation, to help companies be competitive and successful in today's world manufacturing environment.

About International Zinc Association (“IZA”)

The International Zinc Association (IZA) (http://www.zincworld.org) is a non-profit organization, based in Brussels, Belgium, representing the world zinc industry. IZA provides a forum for the zinc industry to address global issues through collaborative efforts in Sustainable Development, Technology & Market Development, Environment and Communications. In addition, research capabilities in the product, environmental and health areas for zinc are provided through the International Lead Zinc Research Organization (ILZRO).

About ZESTec

ZESTec promotes the application and market development for all types of zinc based energy storage systems for a range of end uses from automotive to portable power, for consumer and business use. Membership of the ZESTec consortium includes Zinc Producers (Xstrata, Horsehead, Grillo, Industrias Peñoles, TeckCominco, and Zinifex) and Zinc Energy System Manufacturers (eVionyx, PowerZinc and Power Air Corporation). The activities of the Consortium are being coordinated through the International Zinc Association.

About Power Air Corporation

Power Air Corporation, with head office in Livermore, California, is engaged in the business of developing, manufacturing and marketing fuel cell based commercial products. Power Air has the exclusive worldwide license to zinc-air fuel cell technology that has been developed at the Department of Energy’s Lawrence Livermore National Laboratory, in Livermore, California, for all fields of use (portable, stationary, light mobility and transportation applications) and commercialization.

For further information please call +1-925-960-8779 or visit our website at http://www.poweraircorp.com.

Investor Relations call +1-866-734-7026 or e-mail to investors@poweraircorp.com.

Pate100

Plan of Operations

Gedult ist hier gefragt! Sollten die Ihre Ziele erreichen sehe ich hier einiges

an Potential. Momentan muss man noch nicht investiert sein aber beobachten sollte

man den Wert auf alle Fälle. Es liegt noch viel arbeit vor der Firma!

Plan of Operations

We have determined to focus resources on the development of one ZAFC product that we envision would be manufactured and marketed by an original equipment manufacturer under agreement with us. Our initial ZAFC product will initially be targeted to OEMs delivering power solutions to the business and residential backup and emergency power segment.

We will design our initial prototype for OEM integration into a ZAFC based portable emergency generator designed for back-up or emergency use in homes and small businesses. This generator will be designed to be suitable for use both indoor use, as it will not generate emissions, and outdoor use. The generator will be designed to generate AC power at a rated power output of 1.25 or 2.5 Kilowatts, and to run for four to six hours continuously at fully rated power when fully fuelled. Following the four to six hour operating period, the fuel will be replaced by:

* Replacing the power cartridge on top of the unit, which should take less than one minute and releasing the fuel (zinc) into the hopper and which may be completed while the unit is still operating; and

* Replacing one or more of the electrolyte tanks on the bottom of the unit which should take no longer than two minutes, and will be accomplished without any exposure of the end-user to any electrolyte.

8

We plan to complete the following development work in order to achieve this objective:

Phase

Description of

Development Phase

Description of Development Work

Planned Timing

6

Program Concept

We plan to complete the identification of engineering requirements, the design concept for the prototype and further refine our business plan

Fourth quarter of 2006 and first quarter of 2007

7

Engineering Prototype

With input of an OEM, we plan to complete the design, manufacture and testing of an engineering prototype incorporating our ZAFC fuel cell technology

First and second quarters of 2007

8

Engineering Verification

This phase will consist of further construction and field testing of engineering prototypes

Second and third quarters of 2007

9

Manufacturing Prototype

With input from a manufacturing partner, we plan to design a commercial product with product design freeze and quality plan

Third and fourth quarters of 2007

10

Manufacturing Verification

This phase will consist of the construction and beta testing of manufacturing prototypes and completion of plan for launching the product into the market-place

Fourth quarter of 2007 and first quarter of 2008

11

Pilot Production

This phase will consist of manufacturing pilot units of the product and confirmation that our initial required cost and quality targets have been met

Second quarter of 2008

The above timetable is an estimate prepared by company management based on our plans and objectives as they presently exist, and there are a number of contingencies that could cause our timetable not to be met. While each phase is unique and time limited, specific tasks in multiple phases can overlap. As such, while we are completing Phase 6, the product and technical teams are also undertaking tasks that fall into Phases 7 and 8.

It should be noted that certain core technology development projects will be conducted in parallel with the core ZAFC stack commercialization to ensure the ongoing development of intellectual property, reduce the reliance on third party suppliers for key components, and extend the potential applications for ZAFC technology. One such project that has been identified is an "Air Cathode Development" project. The output of such projects may be 2-3 years in the future but will open up additional market sectors through extended lifetime and lower costs. In all cases, direct spending by the Company on such projects will be minimized through the use of government grants, tax incentives and co-development.

If we are successful in completing the core ZAFC stack commercialization work, then we plan to undertake additional development work in order to expand our range of products incorporating the ZAFC technology. We plan to undertake work on a parallel path to develop the additional ZAFC stack configurations further to OEM specifications and requirements, for products which may include the following:

* a portable generator;

* stationary generators of multiple sizes;

* Uninterruptable power supply back-up systems for computer systems and data centres;

* building, television communications and cable television back-up systems of multiple sizes; and

* auxiliary power units of multiple sizes.

9

We plan to work with OEM's to identify those segments where products incorporating our ZAFC technology will achieve the most commercial success. This process will be integral in our determinations as to what product development we plan to pursue after we complete our additional product development work.

Our ability to undertake our current development work and this future development work will be subject to our ability to obtain the necessary financing to fund this development work. Further, our success in developing our initial product will be critical in enabling us to proceed to future development work. We may be forced to abandon plans for future development work if our initial product is not successful or we do not achieve the required financing.

In undertaking our development work, it will be our intention to continuously enhance our product range and to develop new generations of products. However, we do not plan to divert resources from the initial OEM module development unless significant investment in an alternative application is provided by an OEM. We plan to retain a strategic role in the assembly and distribution of products, which will ensure continuity of product service and quality for customers.

In undertaking our development work, we plan to outsource materials handling and manufacturing of components to existing component manufacturers. The aim of this strategy is to alleviate capital costs in the setting up of manufacturing plants, and this will provide flexibility in sourcing of components and compliance of design specification rules in each country.

Jetzt anmelden und diskutieren

Registrieren

Login

Zum Thread wechseln Häufig gestellte Fragen zur Power Air Corp Aktie und zum Power Air Corp Kurs

Am 01.10.2009 gab es einen Split im Verhältnis 10:1.

Am 01.10.2009 gab es einen Split im Verhältnis 10:1.

Nein, Power Air Corp zahlt keine Dividenden.